Certified piping for

liquids under pressure

Components for industrial plants

We produce various types of piping and customised components: bundles, connecting tubes and customised ducts, designed for use on plants with European PED certification.

Working closely with our engineers enables us to identify and solve potential critical issues, ensuring a high-performance process plant in the long term.

Each step of the operational process is carefully monitored and evaluated to ensure maximum quality and safety.

How we make stainless steel tubes

We manufacture and assemble process plants: each component is carefully evaluated in terms of performance.

Our equipment for pharmaceutical, chemical and food applications comes complete with detailed technical documentation to ensure compliance with all industry regulations.

The production steps of preparation, filtration, sterilisation, fermentation and storage installations are fully customised to meet the specific needs of each industry.

Do you want to find out how we can integrate your next pharmaceutical installation?

Special machinery for the safety of food and pharmaceutical installation

Our attention to detail can also be found in our selection of machinery.

The use of these technologies reduces the number of joints and fittings in the system: we can thus avoid the accumulation and deterioration of any residues, without the risk of affecting the quality of the final preparation.

Extrapolation plant

It is a versatile tool with which to handle tubes in a controlled and precise manner, enabling a variety of maintenance, repair and modification operations. We model the shape and size of tubes without using additional fittings. Material waste is minimised, optimising costs and time without sacrificing a customised system.

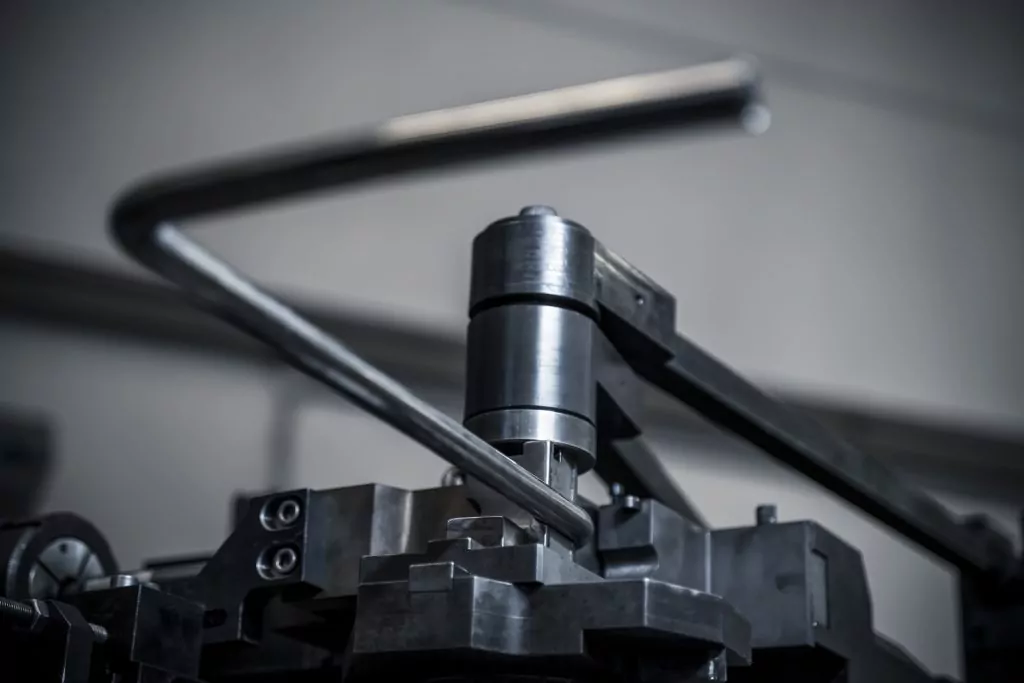

Tube bending plant

We adapt the tubes to different shapes, bends or angles based on specific design and installation requirements.

There are many advantages: precision and repeatability in curved shapes, greater design flexibility, time and material savings by avoiding cutting and welding of tubes.